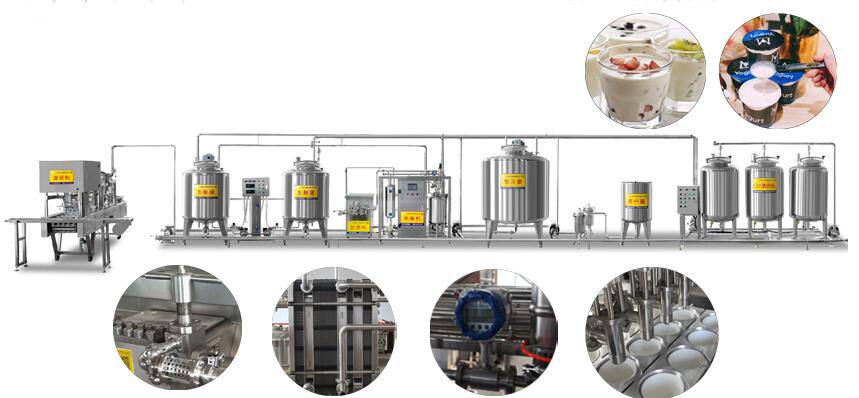

500L/H Plate type yogurt production line

Technical parameters of 500L / h plate type yoghurt production line:

Output: 500l-3000l (customizable)

Sterilization temperature: 70-90 ℃ (settable)

Sterilization time: 15-300 seconds (customizable)

Heating mode: electric heating or steam heating

Refrigeration mode: compressor refrigeration or ice water unit refrigeration

Fermentation temperature: 30-50 ℃ (depending on the strain)

Filling method: cup and bottle (customizable)

Refrigeration temperature: 2-10 ℃ (adjustable)

Total power: 126kw

500L / h plate yogurt production line

Workflow: milk feeding → double filtration → refrigeration and storage of raw milk → preheating → homogenization → pasteurization → yoghurt inoculation and fermentation → filling → CIP cleaning

1. The 500L / h plate yogurt production line is mainly composed of unloading tank, double filter, raw milk refrigeration storage tank, full-automatic 4-stage plate sterilizer, high-pressure homogenizer, fermentation tank, full-automatic horizontal cup filling machine and CIP on-site cleaning system.

2. The equipment is designed and manufactured according to the processing technology of yogurt. It is equipped with a full-automatic 4-stage plate sterilizer, which can set the discharging temperature by itself, without secondary heating, and can directly put in the bacteria. The operation of the equipment is simple, which only needs 3-4 people to operate in the whole process, reducing the user’s labor cost.

3. The equipment is equipped with a separate yoghurt fermentation water supply system, which makes the equipment more uniform in the process of yoghurt fermentation, and the yoghurt products produced have stable quality control and better taste.

4. The 500L / h plate yogurt production line is equipped with sanitary digital flowmeter, which is accurate in measurement and convenient for users to accurately put strains and ingredients according to the flow of fresh milk.

5. The equipment is suitable for small and medium-sized dairy enterprises, ranch processing centers, yogurt factories and other places. The equipment can be used for processing stirred yoghurt, supporting air-cooled yoghurt machine or fermentation room to produce solidified yoghurt, or adding fresh milk refrigeration tank and filling machine to produce fresh milk. It is especially suitable for self built dairy processing plants in dairy farms. It is a set of relatively high cost performance The yogurt production line.